-

Products

Category

Category

Galaxy Series

Galaxy Series

Engineering plastics and products testing machines

Engineering plastics and products testing machines

Plastic pipe & Pipe fitting valve testing machines

Plastic pipe & Pipe fitting valve testing machines

Ultra-high molecular weight polyethylene testing machines

Ultra-high molecular weight polyethylene testing machines

Plastic manhole testing machines

Plastic manhole testing machines

Thin-walled stainless steel pipes & fittings testing machines

Thin-walled stainless steel pipes & fittings testing machines

Specimen Preparation

Specimen Preparation

Other testing machines

Other testing machines

Reference Material

Reference Material

Standard

Standard

GB Standard

GB Standard  GB Standard

GB Standard  IS0 Standard

IS0 Standard  IS0 Standard

IS0 Standard  ASTM Standard

ASTM Standard

- About us

- News

- Services

- Mall

International marketing line:86-314-2296011

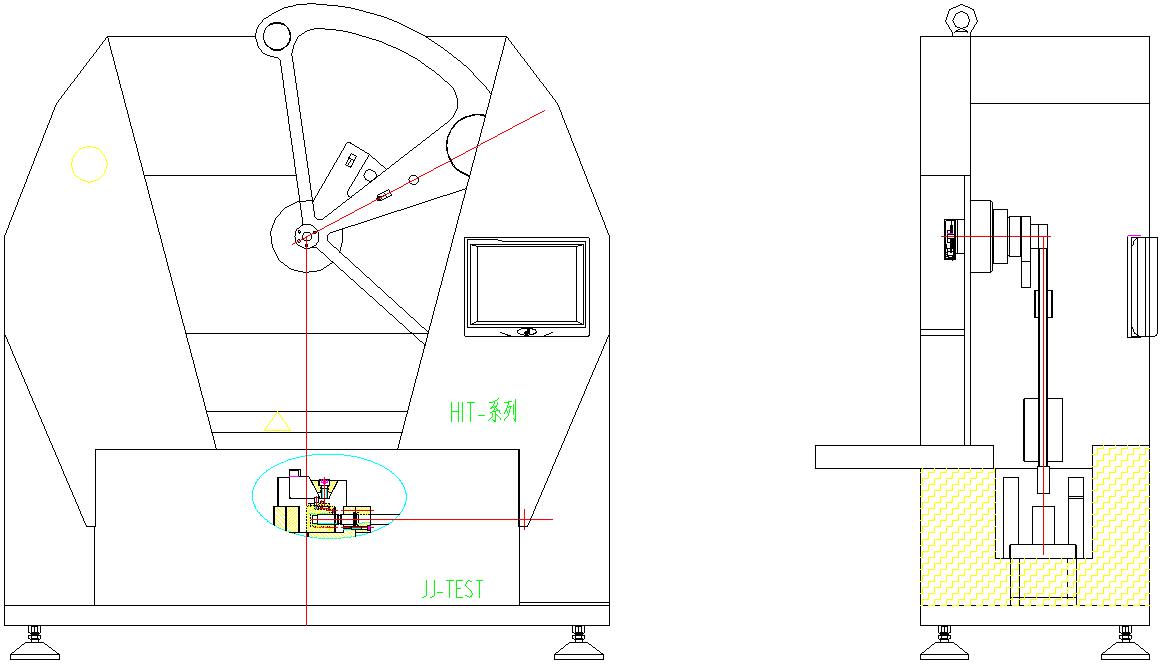

Hit-245x low temperature pendulum impact testing machine

Source:Chengde Jinjian Testing Instrument Co., Ltd Views:2998 Time:2021-01-26

1、 Product description

Low temperature pendulum impact combined impact testing machine is mainly used to measure the impact strength of engineering plastics, glass fiber reinforced plastics, ceramics, cast stone, plastic electrical appliances, reinforced nylon, electrical insulation materials and other non-metallic materials at low temperature and normal temperature. It is an ideal testing equipment for chemical industry, scientific research institutions, colleges and universities, quality inspection departments, professional manufacturers and other units.

The instrument adopts bipolar refrigeration system to realize low temperature impact test as low as - 50 ℃. The instrument is composed of a composite impact tester, a cooling source and an environmental test chamber. The main engine of the pendulum impact testing machine adopts the compound sector pendulum structure with patented technology, which has two test functions of cantilever beam and simply supported beam. After the experience and recognition of numerous users, it has passed the CNAs test for many times, and the test results are satisfactory, which can provide you with the most reliable test data. The refrigeration system adopts distributed control structure with strong modularity, fast refrigeration and high control precision. The sample is placed on the simply supported beam bracket and cooled directly. Compared with the traditional separate refrigeration box, the test temperature is more accurate without sample transfer. Through the sample pool to be tested in the test chamber, multiple splines can be cooled at the same time, which greatly reduces the low-temperature cooling time of the sample. One sample can be impacted by directly placing another sample, and the test efficiency is very high. The upper cover of the test chamber is opened automatically in the form of impact, so the heat loss is small and the temperature change is very small.

2、 Product features

1. One machine with multiple functions can be used for cantilever beam impact test, simply supported beam impact test, low temperature impact test as low as - 50 ℃ and normal temperature test;

2. The sector pendulum (pendulum) with high technical content has good rigidity, no vibration and small wind resistance, which ensures the accuracy of test results;

3. The unique simply supported cantilever composite hammer blade is the technical core and soul of the product;

4. Automatic identification of test method, automatic measurement of pre elevation angle and automatic calibration and correction of energy loss;

5. Automatically correct the energy loss caused by air resistance and mechanical friction, and use the corrected impact energy for display and strength calculation;

6. The refrigeration system adopts the distributed control structure that the cooling source and the low temperature environment box are set independently. The cooling source adopts the bipolar refrigeration technology for refrigeration and reserves the cold source. The cold source is transmitted to the low temperature environment box through the air duct. The system test box has good modularization, fast cooling speed and stable temperature control;

7. The sample to be tested is placed on the sample support jaw of the test chamber to cool down. When the temperature reaches the required temperature, the upper sealing cover is opened to reduce heat loss. The cover of the test chamber is opened by the cylinder, and the impact test is carried out directly after opening, which subverts the traditional low temperature test method and makes the test temperature of the sample closer to the required temperature of the theoretical test;

8. The test chamber is covered with aluminum sheet layer, which not only increases the internal beauty of the test chamber, but also is the "accumulator" of the test chamber. It increases the low-temperature buffer capacity of the test chamber, ensures the temperature of the test chamber during impact, and improves the test efficiency;

9. The air source box can be used as the test bed of the pendulum impact testing machine while providing the cold air source, which saves the test space and makes the whole equipment more integral and beautiful;

10. There are several sample placing racks in the test chamber. The samples on the rack can be cooled at the same time. One sample can be impacted by placing another sample directly after impact. The test efficiency is very high.

11. Multi language interface provides friendly input and display interface, supports Chinese, English, French, Italian, German and other languages, and can meet the needs of customers in different countries and regions;

12. The seamless switching between the full-color touch screen control form and the PC control form makes the operation more flexible and convenient, and highlights the personality;

13. USB removable memory interface can store a lot of test data;

14. The test results can be stored, counted, analyzed, printed and exported by PC software;

15. With a number of automatic safety protection and protection, the safety is very high;

-

2025-12-09

-

2025-12-09

-

2025-12-09

-

2025-12-09

-

2025-12-09

-

2025-12-09

-

2025-12-09

-

2025-12-09

-

2025-12-09

-

2025-12-09

Contact

E-mail:jj-test@jj-test.comWeb:www.jj-test.com

Add:No.1 Block J, Innovation and Technology Park, High-tech Development Zone, Chengde, Hebei, China

Scan to learn more about products

Get more information

copyright @ 2020 Chengde Jinjian Testing Instrument Co., Ltd ALL rights reserved Privacy Policy

Language

Language

中文

中文 EN

EN RU

RU

Consult Now

Consult Now

jj-test@

jj-test@

+86-314-2296011

+86-314-2296011