|

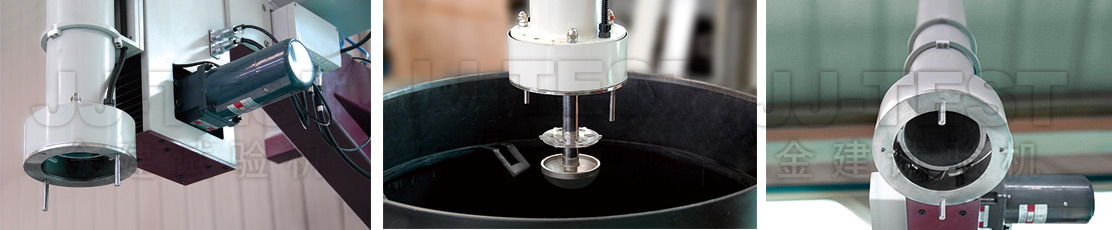

JJICI Manhole Impact Tester

This instrument is used to test the impact resistance of plastic manhole base and wellbore wall. It is a necessary testing instrument for plastic manhole testing institutions, production and construction units. |

|

|

|

||

|

1. Unique modular design, mainly including sample support base, lifting device, protective tube drop hammer device, power system, control unit;

2. Using the principle of vacuum lifting hammer, the suction power is large and the efficiency is high. The hammer falls freely, impacts the sample, catches the hammer in time after impact, and raises the hammer to the impact height at high speed to prevent secondary impact to the sample;

3. Cantilever type liftable structure design, with open test space, convenient for sample installation. Before the impact, the falling hammer is absorbed in the protective tube and extends along with the protective tube to the middle of the flow trough at the bottom of the inspection well. After the protective tube is positioned, press the impact button to freely fall the falling hammer. After the impact, the impact hammer is automatically captured in time. The impact hammer is again absorbed in the protective tube. After the test is completed, the protective tube is raised, and the operation process is safe and reliable. During the flow trough impact test, the applicable inspection well base diameter range: 315mm~Ф1600mm;

4. The protective tube is installed vertically, the inner wall roughness is less than 0.8, the friction is extremely low, and the falling weight speed is not less than 95% of the theory;

5. The protective tube positioning detection device is installed at the bottom of the protective tube, so that the protective tube will automatically drop and stop at 50mm from the impact point. You can also press the stop button to position at any point within the lifting range;

6. The dual-redundant design and application of the limit sensor makes the lifting and positioning control of the protective pipe safer and more reliable.

|

|

|

Standard

|

|

|

BS EN 13598-2

|

DB11/T967 |

|

CJ/T 326

|

CJ/T 233

|

|

JJICI Manhole Impact Tester

|

|||||||

|

Technical Parameter Technical Parameter

|

|||||||

|

Flow trough impact, manhole base diameter range: |

Ф315mm - Ф1600mm

|

||||||

|

Side wall impact, manhole base diameter range: |

Ф315mm - Ф1400mm

|

||||||

|

Drop weight impact height:

|

2.5m

|

||||||

|

Impact hammer type:

|

d90

|

||||||

|

Hammer mass:

|

1.0kg

|

||||||

|

Protection pipe lifting stroke:

|

1.5m

|

||||||

|

Protection pipe lifting speed:

|

1.2m/min

|

||||||

|

Hammer lifting method:

|

Vacuum adsorption

|

||||||

|

Air source:

|

0.5MPa - 0.8MPa Compressed air

|

||||||

|

Power supply:

|

|

||||||

|

|

|

||||||

|

|

|

||||||

Language

Language

中文

中文 EN

EN RU

RU

Category

Category

Engineering plastics and products testing machines

Engineering plastics and products testing machines Engineering plastics and products testing machines

Engineering plastics and products testing machines Standard

Standard

Consult Now

Consult Now

jj-test@

jj-test@

+86-314-2296011

+86-314-2296011