|

MFI-2322H Melt flow rate indexer

This instrument is used to test the engineering plastics such as polyethylene, polysulfone, fluoroplastics and nylon with high melting temperature, as well as plastics with low melting temperature such as polyethylene, polystyrene, polypropylene ABS resin and polyformaldehyde resin. |

|

|

|

||

|

1. The temperature control system of the tester has fast heating speed, high constant temperature accuracy, short temperature recovery time after filling, and can quickly return to constant temperature within 2min; Temperature control is stable and reliable.

The temperature control is stable and reliable.

|

|

|

|

2. The system automatically identifies the effective test range of national standard, ISO standard and American Standard.

|

||

|

3. The control software can realize the functions of parameter setting, constant temperature control, cutting, metering calibration, automatic weight loading, timing, MVR and MFR result display, etc.

|

|

|

|

4. When using MVR, the MVR value of the sample at the specified time can be measured. After weighing the sample, the system automatically obtains the MFR value, which can be compared with the test results of MFR.

|

||

|

5. The system has the function of test parameter storage, and can store 8 groups of test parameters of MFR and MVR.

|

|

|

|

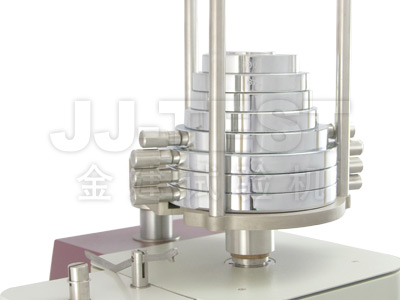

6. The measured results can be automatically transformed into each other, with the function of melt density test, and equipped with automatic weight loading device.

|

|

Standard

|

|

|

GB/T 3682.1-2018

|

GB/T 3682.2-2018

|

|

ISO1133-1:2011

|

ISO1133-2:2011

|

|

JB/T 5456-2016

|

ASTM D 1238-10

|

|

MFI-2322H

|

|||||||

|

Technical Parameter Technical Parameter

|

|||||||

|

Test methods:

|

MVR/MFR

|

Display mode:

|

Full color touch screen

|

||||

|

Loading method:

|

Motorized

|

Measuring range:

|

(0.01 - 3000)cm³/10min

|

||||

|

Temperature control range:

|

(50 - 450)℃

|

Temperature display resolution: |

0.01℃

|

||||

|

Timing accuracy:

|

0.005S

|

Displacement accuracy:

|

±0.02mm

|

||||

Language

Language

中文

中文 EN

EN RU

RU

Category

Category

Engineering plastics and products testing machines

Engineering plastics and products testing machines Engineering plastics and products testing machines

Engineering plastics and products testing machines Standard

Standard

Consult Now

Consult Now

jj-test@

jj-test@

+86-314-2296011

+86-314-2296011