|

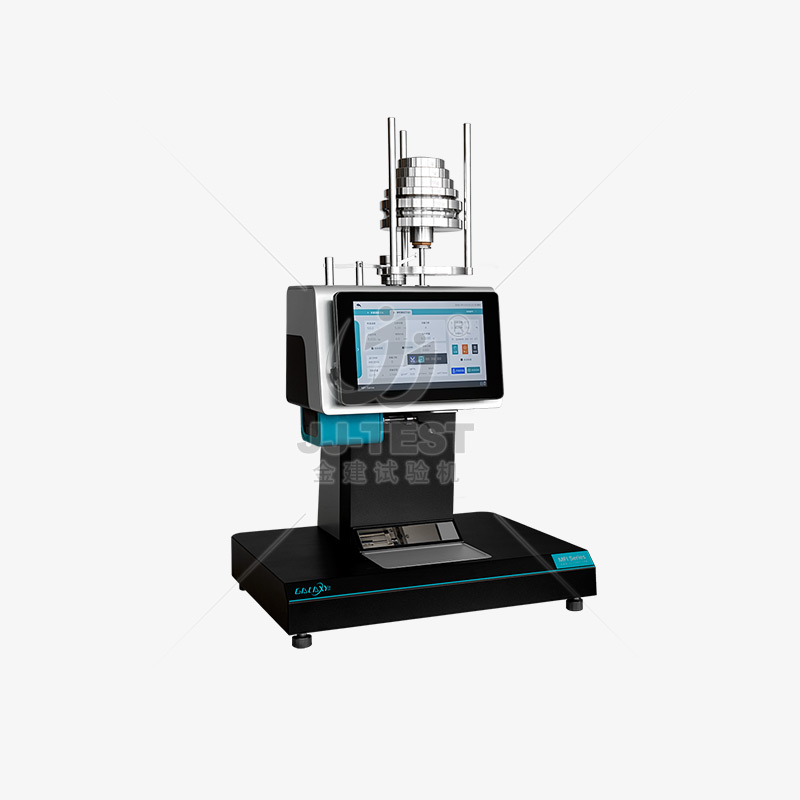

MFI-G3112

GalaxyMelt Flow Indexer

|

|

|

|

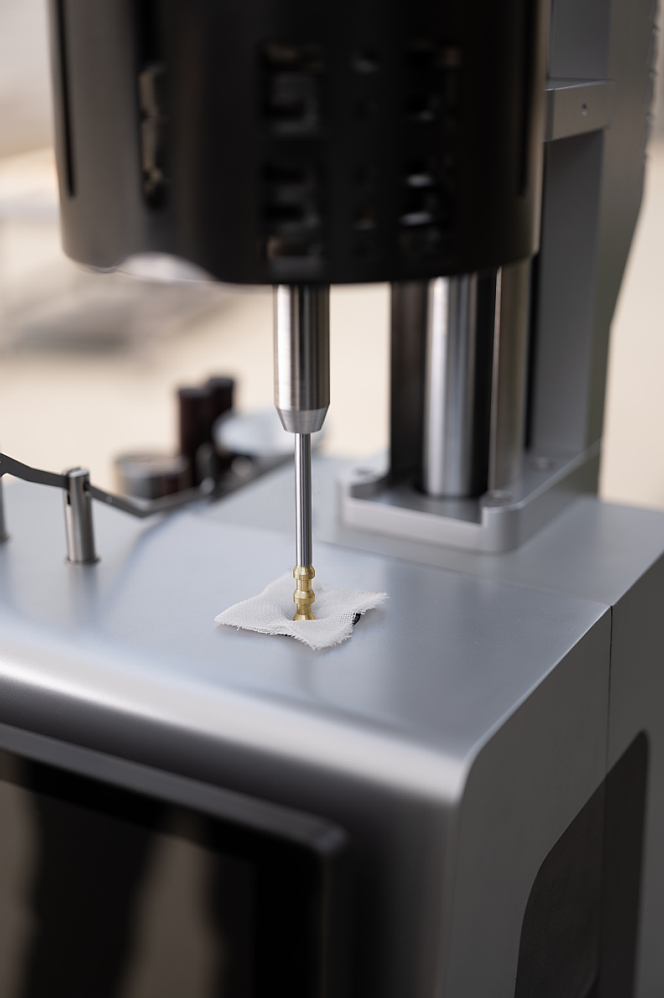

Used to measure the melt mass flow rate (MFR) or melt volume flow rate (MVR) of various plasticsand resins in the viscous flow state. This product is suitable for high-melting-temperature plasticssuch as polycarbonate, polyarylsulfone,fluoroplastics,nylon,etc.,as well as low-melting-temperatureengineering plastics such as polyethylene (PE), polystyrene (PS), polypropylene (PP), ABS resin,polyoxymethylene (POM),etc. It is widely used in raw material production,plastic product manufacturing,as well as in educational institutions,research institutes, and quality inspection agencies.

|

||

|

1.Intelligent Temperature Control

|

|

|

|

Intelligent heat conduction and balanced distribution ensures temperature,deviation with distance within 0.1C;

|

||

|

Adopting digital intelligent control algorithm, with the advantage of quick response, fast & smooth heating and shorter recovery time of temperature;

|

||

|

|

||

|

Long-term continuous working is stable and reliable even at 450C;

|

||

|

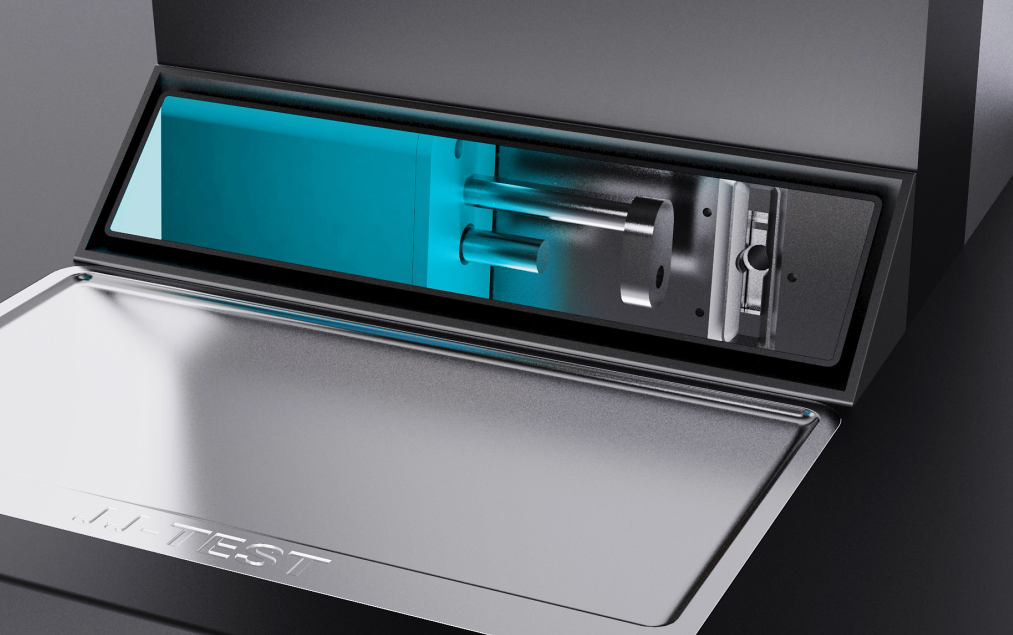

Thermal insulation of the oven made of Eco-friendly materials,adopting integrated molding process,provides excellent insulation perfommance;

|

||

|

2.Powerful Functions & Controllability

|

||

|

|

||

|

The application of temperature-time curves and MVRcurves enables users to intuitively understand thetemperature fluctuation range and the dispersion oftest results;

|

||

|

Built-in multiple test plans,effhcient and practical;

|

||

|

Automatic identifcation of effective test intervalsspecifed in both ISO and ASTM standards;

|

||

|

||

|

Multi-MFI control and data management system,shares data across systems, and enables remotemonitoring with real-time data transfer;

|

||

|

3.MFI-G2 SERIES

|

||

|

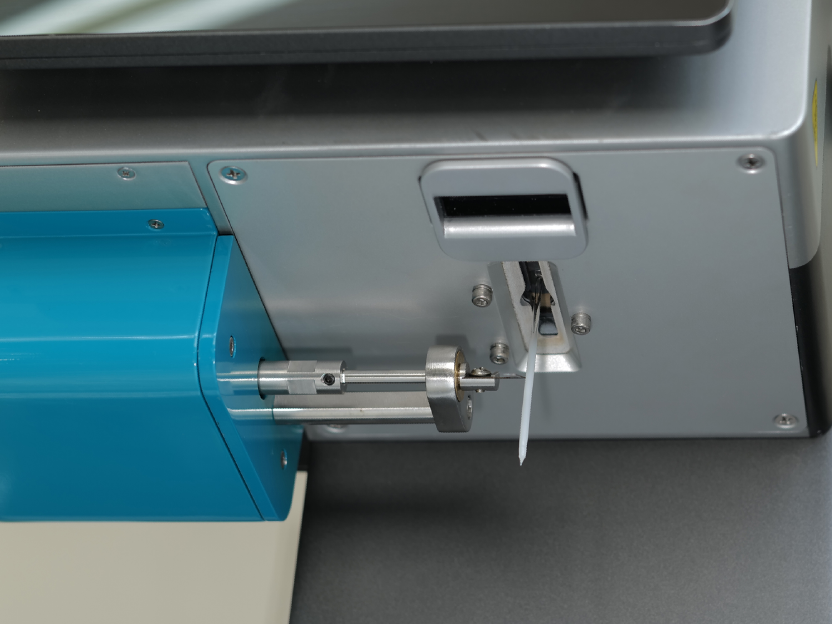

Weights:Pre-setting, software selection,multi-level variable loading;

|

||

|

Automatic load changing and calculation of flow rate ratio (FRR);

|

||

|

Two preloading methods: weight load and pneumatic load,with adjustable preloading positions;

Monitors piston movement in real time to detect sudden stops orspeed changes, ensuring stable tests and reliable data |

|

Standard

|

|

|

GB/T 3682.1

|

GB/T 3682.2

|

|

ISO 1133-1

|

ISO 1133-2

|

|

ASTM D 1238

|

JB/T 5456 |

|

Technical Parameter Technical Parameter |

|||||||

|

Test methods

|

MFR/MVR

|

Display mode

|

Touch screen

|

||||

|

Measurement range

|

(0.1~100)g/10min (0.01~3000)cm³/10min

|

Timer resolution

|

0.0005s

|

||||

|

Temperature control range

|

(50~450)℃

|

Temperature display resolution

|

0.01℃

|

||||

|

Temperature indication error

|

≤±0.2℃

|

Temperature recovery time

|

≤2mim

|

||||

|

Test load method

|

Weight preset(Automatically select load)

|

Preload

|

Automatic

|

||||

|

Multi-level variable load function

|

Have

|

Piston displacement display resolution

|

0.001mm

|

||||

|

Mouth gag

|

Manual

|

Compaction method

|

Pneumatic (with a large force value, up to 60kg)

|

||||

|

Excess material extrusion method

|

Manual/Weight(The force value can be set to 60kg for larger values)

|

Barrel cleaning

|

Manual/Pneumatic

|

||||

|

Instrument size

|

(570*470*1450)mm

|

Host quality

|

About 120kg

|

||||

Language

Language

中文

中文 EN

EN RU

RU

Category

Category

Galaxy Series

Galaxy Series Galaxy Series

Galaxy Series Standard

Standard

Consult Now

Consult Now

jj-test@

jj-test@

+86-314-2296011

+86-314-2296011