|

||

|

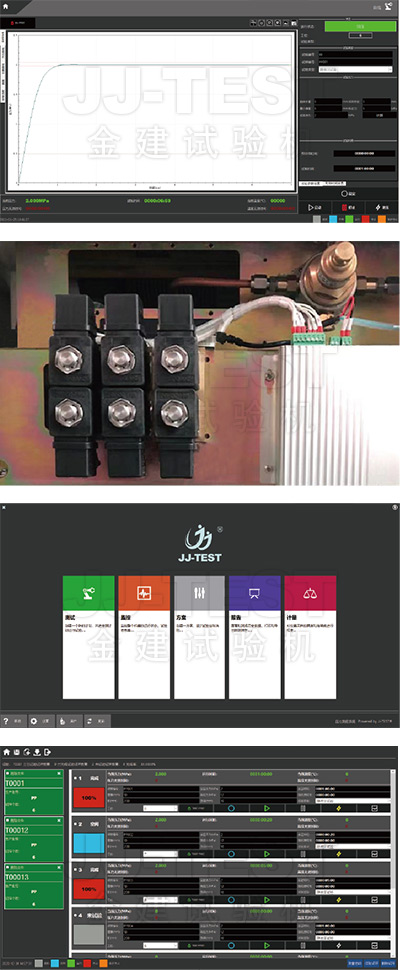

JJGST-S Air Tightness Tester

The instrument is the air pressure test bench unit of the comprehensive performance test platform of thin-walled stainless steel pipe fittings.

|

JJATS-S Hydraulic Pressure Tester (host)

The instrument is the core of the air pressure test control of the comprehensive performance test platform for thin-walled stainless steel pipes and pipe fittings. It can provide accurate test pressure for multiple air tightness test units, multiple pull-out test units, multiple heat resistance test units, etc. at the same time. |

|

JJGST-S Air Tightness Tester

|

1. High security protection TThe transparent explosion-proof glass + stainless steel inner net double protective structure box cover design ensures the safety of the test, and can clearly observe the test process;

The lifting control of the sample rack is interlocked with the opening of the box door, and the lifting operation is prohibited after opening the box, which effectively protects

the safety of the test personnel.

|

|

2. Efficient and convenient operation Multi-station design, support synchronous test, improve test efficiency; Fully open box cover structure supported by gas spring, no obstacle for operation; Unique sample mounting frame, suitable for a variety of specifications of the sample;

|

|

|

3. Automatic invasive leak detection Set up a leak detection bath, which can intuitively and quickly identify leaks; Equipped with one-button automatic sample intrusion device, easy to operate; Equipped with medium water overflow and collection devices,

safe and environmentally friendly;

|

|

1. Excellent pressure control performance Adopt exclusive pressure controller to realize high-speed acquisition and precise control of pressure data. Special solenoid valve for pneumatic control, unique control structure and special sealing material, excellent control performance and durability. Intelligent pressure control algorithm, fast boost, constant pressure and stability. |

|

|

|

2.High stability and high reliability design The unique pressure buffer hardware structure design makes the pressure control more stable;

Modular design of valve-guided solenoid valve, the instrument has long-term stability;

Use international famous brand pressure sensor. |

||

|

3. Powerful software functions Test management and measurement and control are highly integrated. Based on the test task management mechanism. Based on the concept of networked laboratory management. Support customizable test process. Support multi-sample group report mode. |

||

|

4.Efficient and easy to use Touch design, guided operation, simple training, you can quickly start the test. Progress bar, status color, the use of icons, and the test operation are more intuitive and efficient. The whole process of boost curve, real-time curve, long-term curve, data, etc. can be traced and monitored. The test report can be customized to generate and export in multiple formats. |

|

Standard

|

Standard name

|

|

GB/T 19228.1-2011

|

GB/T 33926-2017 |

|

CJ/T 151-2016 |

CJ/T 152-2016

|

|

CJ/T 520-2017 |

|

|

|

|

JJGST-S Air Tightness Tester

|

|||||||

|

Technical parameter Technical Parameter

|

|||||||

|

Work pressure

|

(0.2~3 )MPa

|

Test station

|

2工位

|

||||

|

Applicable scope of pipe diameter

|

DN12~DN300

|

||||||

|

|

|||||||

|

JJAST-S Hydraulic Pressure Tester (host)

|

|||||||

|

Technical Parameter Technical Parameter

|

|||||||

|

Work pressure

|

(0.2~3 )MPa

|

Test medium

|

Compressed air

|

||||

|

Pressure control range

|

(-1%~2%)Set

|

Pressure resolution

|

0.001MPa

|

||||

|

Timer working time

|

0~10000Hour

|

Timing error

|

±0.1%

|

||||

|

Host pressure interface

|

3 stations (1~20 stations can be configured as required)

|

Applicable scope of pipe diameter

|

DN12~DN300

|

||||

|

|

|

||||||

Language

Language

中文

中文 EN

EN RU

RU

Category

Category

Engineering plastics and products testing machines

Engineering plastics and products testing machines Engineering plastics and products testing machines

Engineering plastics and products testing machines Standard

Standard

Consult Now

Consult Now

jj-test@

jj-test@

+86-314-2296011

+86-314-2296011