|

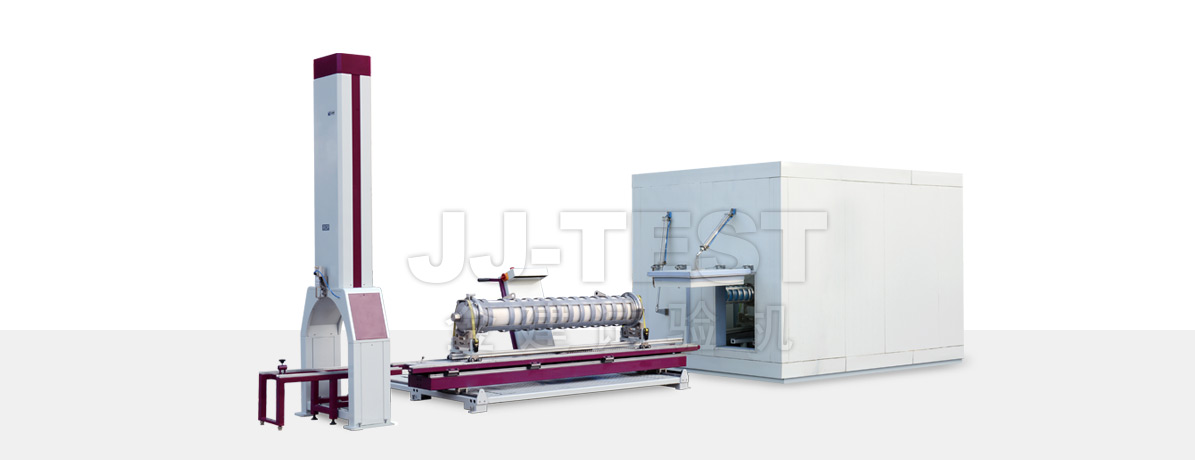

RCP Pipe Rapid Crack Propagation Tester

|

|

|

It is mainly suitable for the performance test of the critical pressure and critical temperature of the rapid crack propagation resistance of thermoplastic pipes that transport gas or liquid.

|

RCP Rapid Crack Propagation tester

|

RCP Test Frame

1. Rational structure and accurate impact speed. There is energy storage device in basic unit, which shall convert elastic potential energy into kinetic energy, that the impact speed range can be controlled between 1mis and 20m/s.

2. lndustrial control terminal was introduced and colorful touch screen display provides more information to operator, such as sample pre-treatment time, pipe inside current pressure, impact speed, length of crack and test temperature, etc.

3. Fast pressure filling and accurate pressure control. For pipes DN200 to DN500, setting pressure can be arrived within 30s.

4. Thanks to the module design, system can be updated and extended to be suitable for different sizes of pipes.

5. High rigid frame enhance the bearing strength of system and multiple buffers in the frame reduce impact force from the high velocity striker, so that the component connection keep perfect after repeated trials.

6. High-efficiency and reliable energy storage system.Energy storage system with a high storage speed and striker lifting system can be locked firmly or released quickly.

7. The easily adjustable support and the simple assembly & positioning system with quick coupling saves time and has proved to work outstandingly well in operation with samples.

8. Automatic security confirmation system. It means the correct locations of the test sample and the striker blade are identified automatically, so that the collision of the sample assembly with the striker blade is prohibited and the blade will not be released when the sample is not in position. |

|

RCP Low Temperature Conditioning Cabinet

The RCP low temperature conditioning cabinet is an essential equipment for the critical temperature test in the fast crack growth resistance test of thermoplastic pipes conveying gas or liquid. Features:

1. Automatically-activated doors are provided.For time-saving reasons, the assembly goes into and out of the conditioning cabinet through the pneumatic opening door.

2. Ultralow temperature and high efficiency. Temperature can drop to-30 within 10min and multiple groups of samples can be treated simultaneously.. Temperature can be monitored and regulated automatically.

3. There are independent sample delivery rails for cooling stations. Unique sealing design for the cabinet avoid freezing phenomenon between sealing strip and cabinet.

4. Excellent thermal insulation system helps to enhance the security and save power consumption.

5. Multiple safety protection systems, including escape and alarm device for operator.

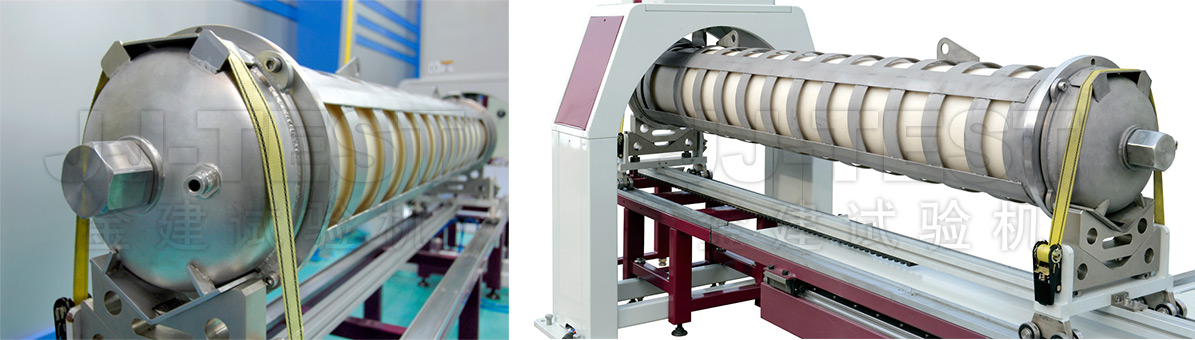

RCP Endcaps

It consists of front & rear sealing part, limiting ring, baffles, o-rings, etc. A variety of specifications are selected,including 63mm,90mm,110mm,160mm,250mm,315mm,400mm, 500mm ,etc. Features:

1. Seal parts, limitation ring and internal baffles are connected to each other, together with sample shall be fixed on the v-support on sample supporting seat. So that blade can impact the slotted area on test pipe.

2. Unique design makes the weight much lighter and with higher rigid which can bear 3Mpa pressure.

3. Patented structure ensures easy mounting and perfect sealing. It is also fast and easy to change to another pipe size or SDR.

|

|

Standard

|

|

|

GB/T 19280

|

ISO 13477 < of resistance to rapid crack propagation (RCP) —Small-scale steady-state test (S4 test) >>. |

|

RCP Rapid Crack Propagation Tester |

|||||||

|

Technical Parmeter Technical Parameter

|

|||||||

|

Max. Pipe diameter:

|

Φ315mm / Φ500mm

|

Impact velocity:

|

5m/s~20m/s

|

||||

|

Accuracy of velocity:

|

±0.5m/s

|

Pressure:

|

≤2.5 MPa

|

||||

|

Accuracy of pressure:

|

0.5

|

Control mode: |

PLC control and touch screen display |

||||

|

|

|||||||

|

RCP Low Temperature Conditioning Cabinet

|

|||||||

|

Technical Parameter Technical Parameter

|

|||||||

|

Numbers of stations:

|

1, 2, 3, 4,,,,N

|

Capacity:

|

1 statiaon: 6m³; 2 stations: 10.5m³; 4 stations: 20m³ |

||||

|

Max. diameter:

|

Φ315mm / Φ500mm

|

Temperature range:

|

RT to -30℃

|

||||

|

Temp. display accuracy:

|

0.1 ℃

|

|

|

||||

|

|

|||||||

|

RCP Automatic Migration System

|

|||||||

|

Technical Parameter Technical Parameter

|

|||||||

|

Numbers of stations: |

1, 2, 3, 4,,,,N

|

Max. diameter:

|

Φ315mm / Φ500mm

|

||||

|

Sample conveyor:

|

Pneumatic & motor-driven |

Distance between stations (manual): |

960mm

|

||||

|

Sample delivery distance:

|

3400mm

|

Sample delivery speed:

|

370mm/s

|

||||

|

Longest time for sample delivery: |

≤30s

|

Air supply:

|

<0.8Mpa (User-provided)

|

||||

|

|

|

||||||

Language

Language

中文

中文 EN

EN RU

RU

Category

Category

Engineering plastics and products testing machines

Engineering plastics and products testing machines Engineering plastics and products testing machines

Engineering plastics and products testing machines Standard

Standard

Consult Now

Consult Now

jj-test@

jj-test@

+86-314-2296011

+86-314-2296011