|

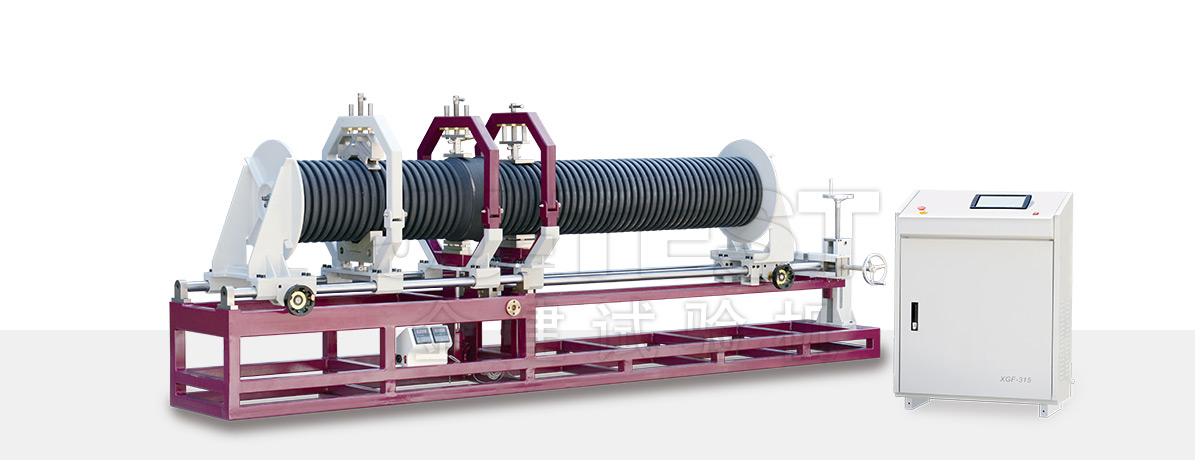

JJAST-102 Piping System Joints Leak Tightness Tester

|

|

|

This instrument is mainly used to test the fitting performance between the pipes when the plastic pipes such as polyvinyl chloride, polyethylene, polypropylene and other plastic pipes are connected by elastic sealing ring, that is, to detect the sealing problem of the interface; insert the pipe section into the socket pipe section Make the sample in the middle, and make the axis of the two pipe sections into a deformation angle, keep it for the specified time under the specified two negative pressure conditions, and check whether the sample leaks during the test. This product is ideal for testing units, production units, and scientific research units. Test equipment.

|

|

1. Industrial color LCD touch screen, arbitrary test pressure setting from 0 to -0.08MPa, programmable pressure control in stages; convenient for checking data, and providing abundant test time pressure curve and other information.

2. The test data can be stored in the U disk to realize massive data storage. Data storage adopts general format, no professional software is needed, and general office software can be used to query.

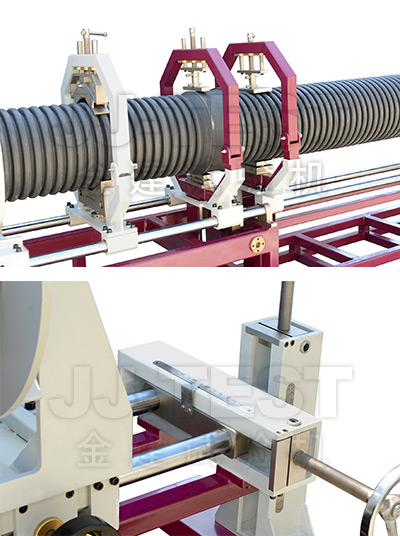

3. Hydraulic pipe radial deformation device, digital display meter head size deformation monitoring, and can automatically adjust the center, the operator can easily save effort when pressure is applied to the thick-walled pipe.

4. Different specifications of pipe fittings are equipped with corresponding support blocks to make the operation more simple and clear.

5. The deflection direction is any deflection angle in the four directions up, down, left, and right.

6. In order to facilitate the installation of samples with relatively large pipe diameters, the sample tightening device adopts a structure in which the upper cover can be opened. |

|

|

Standard

|

|

|

GB/T 10002.1

|

GB/T 10002.2

|

|

GB/T 18477.3

|

GB/T 19472.1

|

|

GB/T 5836.1

|

GB/T 20221

|

|

GB/T 19472.2

|

ISO 13844

|

|

ISO 4422-2

|

|

|

JJAST-102 Piping System Joints Leak Tightness Tester |

|||||||

|

Technical Parameter Technical Parameter

|

|||||||

|

Test method

|

Negative pressure test |

Pressure control range

|

(-0.08~0)MPa

|

||||

|

Applicable pipe diameter range (DN)

|

400mm≤dn≤1200mm

|

Test medium |

Air

|

||||

|

Maximum deflection angle

|

3°

|

|

|

||||

Language

Language

中文

中文 EN

EN RU

RU

Category

Category

Engineering plastics and products testing machines

Engineering plastics and products testing machines Engineering plastics and products testing machines

Engineering plastics and products testing machines Standard

Standard

Consult Now

Consult Now

jj-test@

jj-test@

+86-314-2296011

+86-314-2296011