|

|

JJHBT series Hydrostatic Pressure Tester

|

|

|

|

|

|

Hydrostatic Pressure Tester is mainly used for long-term internal pressure resistance test and hydraulic instantaneous burst test of various fluid transportation pipes such as thermoplastic pipes, composite pipes, steel pipes, engineering hydraulic pipes, oil pipes and automobile pressure pipes; Stability performance (110 ℃, 8760h), pipe resistance to slow crack growth (notch test), pipe fitting system adaptability and other tests under pressure test.

The products sell well in China and are exported to more than 50 countries and regions in Europe, America and Asia.

|

|

The Hydrostatic Pressure Tester consists of three parts: the main engine (pressure control system), the JJtank series thermal tank and the special encap (head). Among them, JJtank and the special head can be connected with different workstation hosts to complete the whole experimental process together. The following are respectively:

|

||

|

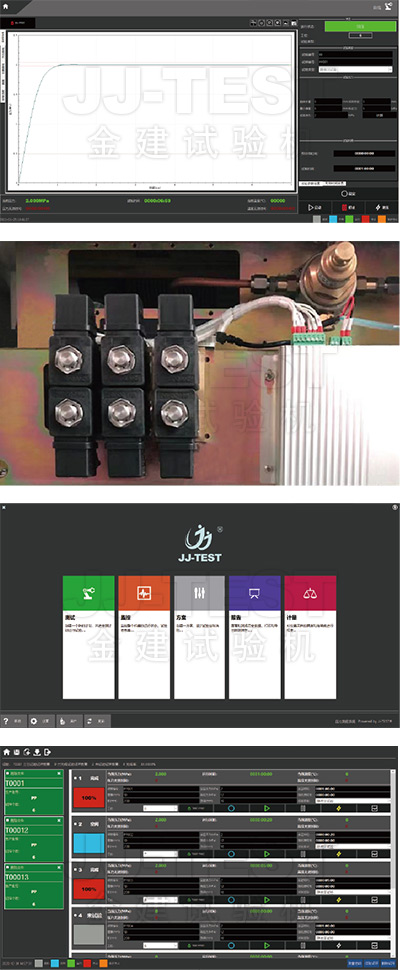

JJHBT series Hydrostatic Pressure Tester host (pressure control system)

The product has multiple specifications and models, and the pressure test range is from 0.02MPa to 350Mpa. The pressure control system adopts a modular design and a dual-loop pressure measurement and control structure. When the pressure is raised, the system automatically judges the diameter of the pipe and the swelling characteristics of the pipe and formulates a boosting plan. The boosting is stable and fast, and the constant pressure is accurate and stable. The supplementary pressure system is not easy to block, adapts to a wide range of water quality, is not afraid of scaling, has sensitive action, low noise and long service life. |

||

|

||

|

1.Excellent pressure control performance

Adopt exclusive pressure controller to realize high-speed acquisition and precise control of pressure data;

Special solenoid valve for pneumatic control, unique control structure and special sealing material, excellent control performance and durability;

Intelligent pressure control algorithm, fast boost, constant pressure and stability.

2.High stability and high reliability design

The unique pressure buffer hardware structure design makes the pressure control more stable;

Modular design of valve-guided solenoid valve, the instrument has long-term stability;

Use pressure sensors of internationally renowned brands.

3.Powerful measurement and control software

Test management and measurement and control are highly integrated;

Based on the test task management mechanism;

Based on the concept of networked laboratory management;

Support customizable test process;

Support multi-sample group report mode.

|

|

|

JJTANK Thermal Tank

The JJTANK Thermal Tank is the necessary equipment for the long-term hydrostatic test and hydraulic instantaneous blasting test of pipes and fittings, and provides the required ambient temperature during the test. JJTANK series Thermal Tank has more than 30 specifications and models , which are suitable for different pipe sizes (maximum pipe diameter DN2000mm), and can also be specially customized according to customer requirements.

2. High-quality thermal insulation layer, when the water temperature is 95 ℃, the outer frame is still close to room temperature, which greatly improves the safety of the whole machine, and at the same time, the power consumption can be saved by more than 70%;

3. The technical problem of gas overflow in the tank is completely solved. The medium box is equipped with a steam collection device, so that the gas does not overflow at high temperature;

4. The bottom of the structural frame has a large bearing weight and strong deformation resistance;

5. Pneumatic tank cover, controllable at any position, easy to observe;

6. Intelligent water replenishment can ensure that the temperature in the tank does not fluctuate greatly due to water replenishment. The temperature fluctuation caused by water replenishment is less than 0.1 °C, and the temperature is uniform and stable, saving time and effort;

7. Multi-station, multi-group and multi-port, independent connection, and equipped with large and small diameter sample water filling device, no need for users to configure separately.

JJEC series Pipe & Pipe fitting Endcap (head)

This series of products is an essential supporting product for pipes, pipe fittings with internal pressure resistance, hydraulic instantaneous blasting and pipe suitability pressure test. Port sealing of pipes and fittings such as walls, structural walls, metal composites, etc.

The Endcaps of pipes and pipe fittings are patented products of our company. They are made of 304 stainless steel and high-quality carbon steel. They have simple structure, convenient operation, good sealing performance, high strength, light weight and corrosion resistance.

1. φ10~φ800 are processed by precision casting, φ900~φ1600 are mechanical head, and the seal adopts A-type radial sealing structure, all materials are made of high-quality stainless steel, and the outer surface of the fixture parts is uniform in stainless steel, with high strength and corrosion resistance.

2. The Endcap is a patented product with simple structure and convenient operation. During the test, the process flow of first loading the card and then sealing is realized to ensure that the sealing of the card is 100% leak-free.

3. There is no need for special mounting brackets when assembling the Endcap, and safety hoisting devices are available for parts above 3kg.

4. The split-type clamping block structure can realize automatic centering and make the pipe fittings more firmly clamped; the clamping block is designed as a hollow structure, which is light in weight and easy to handle and assemble while ensuring the strength. During the pressing process, the inner seal of the head can be observed in real time. The weight of the DN400 tightening block is 7.3kg, and the total weight after single-end assembly is ≤50kg.

5. It is supported by a ring-shaped elliptical head, which can effectively prevent the bottom of the Thermal Tank from being bumped and deformed when the fixture is placed in the Thermal Tank.

6. Modular design is adopted, which is processed and manufactured through molds and tooling. The parts are consistent and interchangeable, and the pressure resistance can be upgraded by replacing necessary parts.

7. Good versatility, the interface can be used with the pressure host and constant Thermal Tank of various foreign manufacturers.

1. Stainless steel inner tank, equipped with stainless steel pump body;

|

Standard Standard

|

||

|

GB/T 6111

|

GB/T 15558

|

GB/T 13663

|

|

GB/ 15560

|

GB/T 18477

|

GB/T 10002

|

|

SY/T 6770

|

SY/T 6267-200

|

SY/T6267-2006

|

|

SY/T6662

|

IS0 1167

|

ASTM D1598

|

|

ASTM D1599

|

||

|

JJHBT series

|

|||||||

|

Technical parameter

|

|||||||

|

Control mode:

|

Industrial tablet PC /digital tube display terminal + PC

|

Test pipe diameter:

|

Φ2mm - Φ2000mm

|

||||

|

Numbers of stations:

|

3/5/10/20/25/30/50 (customizable)

|

Working pressure:

|

0.1/0.6/10/16/20/25/40/60/100/200/350MPa

|

||||

|

Pressure control accuracy:

|

-1% to +2%

|

Display resolution:

|

0.00001/0.0001/0.001/0.01MPa

|

||||

|

Pressure control range:

|

2.5% - 100%F.S

|

Allowable error of indication: |

±1% |

||||

|

Timing range:

|

0 - 10000Hour

|

Timing resolution:

|

1s

|

||||

Language

Language

中文

中文 EN

EN RU

RU

Category

Category

Engineering plastics and products testing machines

Engineering plastics and products testing machines Engineering plastics and products testing machines

Engineering plastics and products testing machines Standard

Standard

Consult Now

Consult Now

jj-test@

jj-test@

+86-314-2296011

+86-314-2296011